Dry underfloor heating, also known as prefabricated floor heating, is a type of underfloor heating system that uses prefabricated groove insulation modules for dry installation, suitable for prefabricated floors and various other buildings that require underfloor heating. It does not require cement backfill and is the counterpart of traditional wet underfloor heating. In a dry underfloor heating system, the heating pipes are installed beneath the floor covering material, directly heating the floor and supplying heat to the room through radiation and convection to achieve a quick and comfortable heating effect. Since dry underfloor heating does not require cement backfill and involves less water, it is more energy-efficient and environmentally friendly compared to traditional wet underfloor heating and offers a higher installation efficiency.

Rapid Heating

Because dry underfloor heating does not have a heavy cement backfill layer, only a thin layer of flooring and an adhesive layer on top, wooden floors can be installed directly. Therefore, it can achieve the desired heating effect in a shorter time, greatly enhancing heating efficiency.

Space-saving

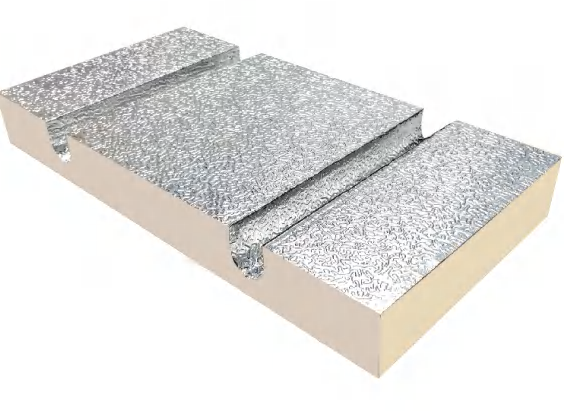

The thickness of dry underfloor heating is relatively thin. The illustrated underfloor heating XPS insulation board use a high-lightness surface layer and insulation core material, which is lightweight. Compared to traditional underfloor heating, it can save a lot of height space, reduce floor load, and increase the effective usable area of the room.

Simple and Quick Installation

The modular design of dry underfloor heating makes the installation process simple and quick, eliminating the cumbersome procedures of traditional underfloor heating like cement backfill and leveling, significantly shortening the construction period and reducing installation difficulty.

Good System Stability

Dry underfloor heating uses environmentally friendly materials, and the heating pipelines are embedded in the grooves of prefabricated modules with a reasonable structure, uniform stress, stable and reliable system that neither clogs nor leaks.

Energy-saving and Consumption Reduction

It can increase to a human-comfortable temperature in just 1 hour, compared to the 4-6 hours of traditional wet underfloor heating, greatly saving on electricity costs. With a high-strength insulation layer composite mortar surface layer below the pipeline, the temperature is not easily dispersed downward, maintaining good constant temperature after heating.

In conclusion, with its rapid heating, space-saving, simple and quick installation, energy conservation, environmental protection, good system stability, and overall energy-saving attributes, dry underfloor heating has been widely used in modern home heating. When choosing to install underfloor heating, one can consider installing dry underfloor heating based on their actual situation and needs.