Roof insulation has always been a key focus in the construction industry. With the continuous advancement of technology, people's demands for buildings have gradually increased. Traditional insulation materials are often limited in certain environments, which is why building materials are constantly being upgraded. XPS boards (Extruded Polystyrene Foam Boards) represent an innovation in insulation materials. XPS extruded polystyrene foam boards are a more advanced and high-performance version of the EPS (Expanded Polystyrene) foam boards, offering improved insulation properties.

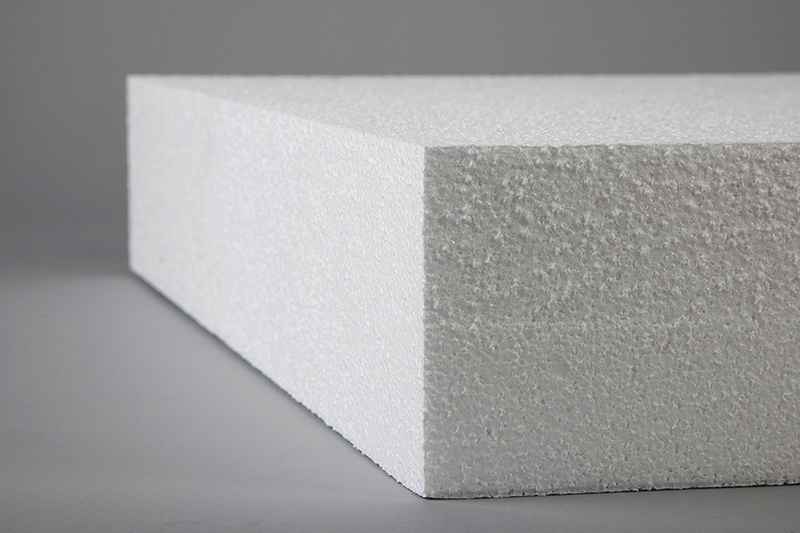

Molded polystyrene foam boards, also known as EPS foam boards or expandable polystyrene foam boards, are made through a process of pre-expansion, aging, molding, drying, and cutting. They can be manufactured into foam products with different densities and shapes, and various thicknesses of foam boards.

EPS foam boards offer several key benefits, including cost-effectiveness and lightweight properties that make them easy to transport and install. They provide good thermal insulation, helping to reduce energy costs, and are durable when kept dry. With their micro-closed cell structure, they are primarily used for building walls, roof insulation, composite board insulation, cold storage, air conditioning, vehicles, ships, floor heating, decorative carving, and many other applications. Their uses are extremely wide-ranging.

While EPS insulation foam boards offer many benefits, they do have some limitations that should be considered when choosing insulation materials. One of the main drawbacks is their moisture sensitivity; although EPS is resistant to some moisture, prolonged exposure to water can cause it to lose its insulating properties and potentially lead to mold growth. Additionally, EPS lacks the compressive strength of other materials like XPS, making it less suitable for applications where heavy loads are involved. Another limitation is its flammability, as EPS can catch fire easily and release toxic fumes when burned, though flame retardants can mitigate this risk. Lastly, environmental concerns arise due to EPS being made from petroleum-based products, which, despite being recyclable, often end up in landfills, contributing to waste.

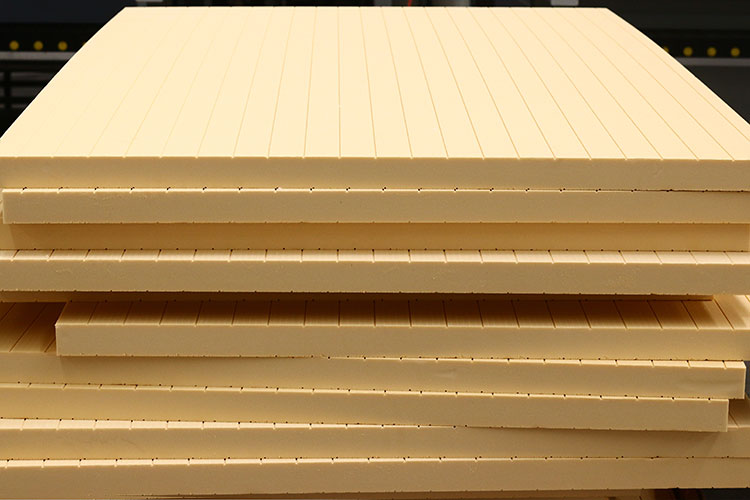

XPS (Extruded Polystyrene) Boards are the third generation of rigid foam insulation materials. They are a type of rigid foam insulation material made from polystyrene resin through an extrusion process. In this process, they overcome the complex production methods of EPS boards. This process involves melting the polystyrene beads and forcing them through an extrusion die, where they form continuous, solid foam boards. The result is a closed-cell foam structure that provides superior thermal insulation, moisture resistance, and durability compared to other types of foam insulation materials like EPS (Expanded Polystyrene).

XPS is made from polystyrene resin and other additives, forming a continuous and surface-honeycomb structure. These thick boards have no gaps in the honeycomb structure. This closed-cell insulation material can withstand different pressures (150-500 KPa) while maintaining the same low thermal conductivity (only 0.028 W/mK), along with excellent long-term insulation and compressive resistance. Its compressive strength can reach 220-500 KPa, making it a high-performance, eco-friendly insulation material with low water absorption, moisture resistance, impermeability, lightweight properties, corrosion resistance, superior aging resistance (virtually no aging with long-term use), and low thermal conductivity.

Learn more about XPS Insulation Compressive Strength.

SOHO Group Extruded Polystyrene Thermal Insulation Board

XPS (Extruded Polystyrene) Insulation Boards are widely used in various construction, industrial, and commercial applications due to their superior thermal performance, moisture resistance, and compressive strength. Here's a breakdown of where and how they are commonly used:

1. Building Insulation

Exterior Walls: XPS boards are commonly used for insulating exterior walls, both in new constructions and retrofits, to improve energy efficiency by reducing heat loss and enhancing thermal comfort.

Roof Insulation: XPS extruded polystyrene foam boards are ideal for flat roofs, pitched roofs, and inverted roofs, where they prevent heat loss, improve moisture resistance, and offer long-lasting performance even in harsh weather conditions.

Floor Insulation: XPS is widely used under concrete floors, including radiant floor heating systems, to provide thermal resistance and minimize heat loss to the ground. It is also used for under-slab insulation in buildings.

2. Foundation Insulation

XPS boards are often used in below-grade applications like basement walls and foundations, where their resistance to water absorption makes them ideal for protecting against moisture and improving thermal efficiency.

3. Cold Storage and Refrigeration

XPS boards are used extensively in cold storage units, freezer rooms, and refrigerated transport to maintain low temperatures efficiently. They provide excellent thermal insulation, preventing temperature fluctuations and reducing energy costs.

4. Below-Grade Applications

Due to its ability to withstand moisture and provide thermal resistance, XPS is used in below-grade insulation applications like under concrete slabs, retaining walls, and perimeter insulation to protect buildings from dampness and maintain insulation performance over time.

5. Insulated Concrete Forms (ICFs)

XPS boards are a key component in Insulated Concrete Forms (ICFs), which are used to build energy-efficient walls by sandwiching concrete between two layers of insulation. XPS provides high thermal resistance and moisture protection, making ICFs ideal for energy-efficient construction.

6. Road and Pavement Insulation

XPS is used in road construction and paving projects to provide frost protection beneath roads, highways, and pavements. It helps prevent frost heave and reduces thermal conductivity, ensuring the stability of the surface during extreme weather conditions.

7. Landscaping

XPS boards are used in landscaping projects for insulating green roofs, garden beds, and outdoor structures, ensuring temperature regulation and preventing soil freezing during colder months.

8. Insulation for High-Load Areas

Due to its high compressive strength, XPS is used in areas subject to heavy loads or high traffic, such as under parking lots, driveways, and areas with substantial foot traffic.

SOHO Group Graphite Insulation Board

1. Superior Thermal Insulation

XPS boards provide excellent thermal resistance, helping to reduce heat loss in winter and heat gain in summer. With a low thermal conductivity (as low as 0.028 W/mK), XPS helps maintain a stable indoor temperature, improving energy efficiency and reducing heating and cooling costs.

2. Moisture Resistance

One of the key benefits of XPS is its closed-cell structure, which makes it highly resistant to water absorption. This makes it ideal for use in areas prone to moisture, such as foundations, basements, and roofs. It helps prevent mold growth and maintains its thermal performance even in wet conditions.

3. High Compressive Strength

XPS insulation boards have a high compressive strength, meaning they can withstand significant pressure without deforming. This makes them ideal for applications where the insulation will be subjected to heavy loads, such as under concrete slabs, roads, and parking lots.

4. Durability and Longevity

XPS boards are durable and resistant to environmental factors like decay, mold, and chemicals. Their long lifespan makes them a cost-effective choice over time, as they continue to provide insulation without significant degradation.

5. Lightweight and Easy to Install

Despite their strength and durability, XPS boards are lightweight and easy to handle, transport, and install. This reduces labor costs and makes them a convenient option for large-scale insulation projects.

6. Resistance to Frost and Freeze-Thaw Cycles

XPS boards provide frost protection, making them especially suitable for below-grade applications like foundations, slabs, and roads. Their ability to resist freeze-thaw cycles ensures long-term stability, even in cold climates.

7. Low Environmental Impact

While XPS is made from petroleum-based materials, many manufacturers are now focusing on reducing its environmental impact by using blowing agents with lower global warming potential (GWP). Additionally, XPS boards can be recycled at the end of their life, contributing to sustainability.

8. Versatility in Application

XPS insulation boards are incredibly versatile and can be used in various applications, including building walls, roofs, floors, and foundations. They are also used in cold storage, road construction, and landscaping projects due to their moisture resistance, thermal insulation, and compressive strength.

Using XPS Insulation Boards offers significant advantages in terms of energy efficiency, moisture resistance, durability, and ease of installation. Whether used in residential, commercial, or industrial applications, XPS is an effective solution for maintaining comfortable indoor temperatures, protecting structures from moisture damage, and ensuring long-term performance in harsh environments.

XPS (Extruded Polystyrene) and EPS (Expanded Polystyrene) both offer distinct advantages depending on the application. When choosing insulation materials for your building projects, understanding the differences between them can help you make the right choice for your needs.

Structure and Moisture Resistance

XPS insulation has a closed-cell structure, making it highly resistant to moisture. This characteristic helps it maintain its thermal performance even in wet conditions, making it ideal for applications like foundations, basements, and cold storage. On the other hand, EPS has an open-cell structure, which means it absorbs moisture over time, potentially reducing its insulation value in damp environments.

Thermal Performance

XPS offers superior thermal resistance, with a thermal conductivity of around 0.028 W/mK, making it more efficient at keeping heat in or out. EPS, while still a good insulator, has a slightly higher thermal conductivity (0.033–0.037 W/mK) and may not perform as efficiently as XPS in extreme conditions.

Strength and Durability

XPS is known for its high compressive strength, which makes it well-suited for high-load applications, such as under-slab insulation or in parking lots. EPS, while durable, has a lower compressive strength and is better suited for lighter insulation applications like wall insulation and roof insulation in residential buildings.

Cost and Environmental Impact

EPS is generally more affordable due to its simpler production process, making it a popular choice for budget-conscious projects. However, XPS offers better long-term performance in high-moisture or high-load situations. In terms of environmental impact, EPS is easier to recycle and has a lower carbon footprint compared to XPS, which is made from petroleum-based materials and is harder to recycle."

As one of the leading insulation board manufacturers in China, SOHO Group offers a breakthrough in insulation technology with its XPS Extruded Polystyrene Boards, featuring Low Internal Stress Technology—a core patent of SOHO. This innovative technology eliminates issues like deformation, cracking, and delamination found in traditional XPS boards, offering twice the stability. It also ensures fluorine-free, bromine-free, and perfectly foamed boards with superior dimensional stability.

With a closed-cell structure, SOHO XPS extruded polystyrene insulation boards provide excellent thermal insulation and moisture resistance, making them ideal for foundations, roofs, and cold storage. Choose SOHO Group for durable, high-performance XPS boards that deliver long-lasting results.

For reliable, high-quality XPS boards, SOHO Group is your trusted supplier.