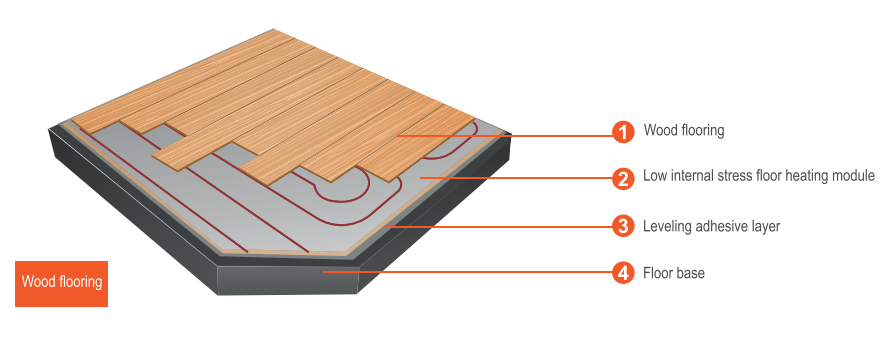

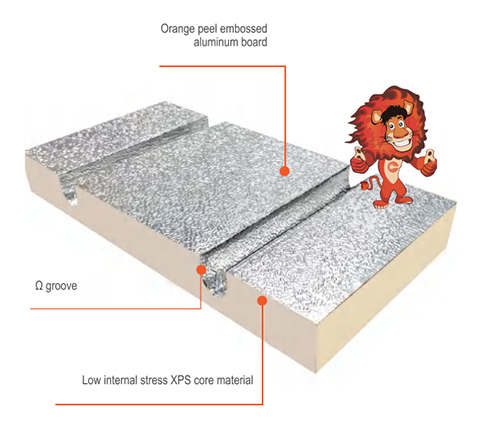

SOHO Group's Underfloor Heating Wooden Floor Boards combine the durability of high-strength XPS extruded foam with the efficiency of an aluminum film heat-spreading layer. These grooved XPS underfloor heating wooden floor boards feature aluminum foil panels that help distribute heat evenly across the floor.

Prefabricated in the factory and assembled on-site, these boards are designed for easy installation. The surface is grooved at fixed intervals, allowing for the seamless laying of heating pipes, providing superior performance in underfloor heating systems.

| Brand | SOHO |

| Product | XPS Underfloor Heating Wooden Floor Boards |

| Material | XPS |

| Thickness (mm) | 30, 35, 40, 50 |

| Length (mm) | 1200, 2400 |

| Width (mm) | 60 |

| Customizable | Yes (to meet specific requirements) |

| Flame Retardant Rating | B1, B2 |

| Compressive Strength (Kpa) | 200, 350, 500, 700, 1000 |

| Water Absorption | ≤1% (v/v) |

| Thermal Conductivity | ≤0.03 W/(m·K) |

| Surface | Aluminum, Foil, Cut, Peel, with Skin |

| *The products are customizable to meet your requirements. | |

Step1. Preparation

Ensure the subfloor is clean, dry, and level before starting.

Step2. Lay the Boards

Lay XPS underfloor heating wooden floor boards with the grooved side up, cutting to fit as needed. Stagger the seams of adjacent boards for better stability.

Step3. Install Heating Pipes

Install heating pipes in the pre-set grooves, following recommended spacing.

Step4. Secure the Boards

Secure the Secure the boards with adhesive or fasteners if necessary. with adhesive or fasteners if necessary.

Step5. Final Checks

Check that the surface is level and seal the edges.

Step6. Install the Wooden Floor

Lay the wooden floor, leaving expansion gaps, and test the heating system.

High-Strength XPS Core: Provides excellent thermal insulation and durability.

Aluminum Heat-Spread Layer: Improves heat distribution for better system performance.

Grooved Design: Pre-set grooves ensure precise placement of heating pipes.

1. Provides exceptional thermal insulation and long-lasting strength.

2. Optimizes heat distribution for superior system performance.

3. Designed for precise and efficient pipe placement.

4. Prefabricated boards for quick, on-site assembly and reduced labor costs.

5. Eliminates the need for double-plating, speeding up installation.

6. B1 and B2 flame retardant grade for enhanced fire safety and compliance with regulations.

7. Formaldehyde-free materials for a healthier indoor environment.

Beijing SOHO Building Materials Group Co., Ltd. is a leading force in China’s energy-saving and thermal insulation industry. Established in 2014, the company has more than 30 years of experience in the sector, with production bases in Tianjin, Hebei, Northeast China, East China, Central China, and multiple international locations. SOHO Group has established a robust domestic and international business network, with products exported worldwide.

Superior Quality: SOHO delivers high-quality products focused on integrity, precision, and professionalism.

Advanced Technology: Our patented Low Internal Stress Technology ensures better stability, durability, and flame resistance, eliminating issues like deformation and cracking.

Eco-Friendly: SOHO XPS extruded polystyrene insulation boards are fluorine-free and bromine-free, offering a sustainable solution.

Innovation-Driven: SOHO stays ahead with cutting-edge technology and continuous innovation.

Customer-Focused: SOHO prioritizes customer satisfaction, providing tailored solutions and exceptional service.

SOHO Group's XPS underfloor heating boards combine cutting-edge technology, superior quality, and environmental responsibility, making them the ideal choice for your flooring and insulation needs.

![]()

If you want to know more about our products, please leave a message or give us a call and we will get back to you as soon as possible.