The low-internal-stress underfloor heating insulation board is a patented product with independent intellectual property rights from Beijing SOHO Group.

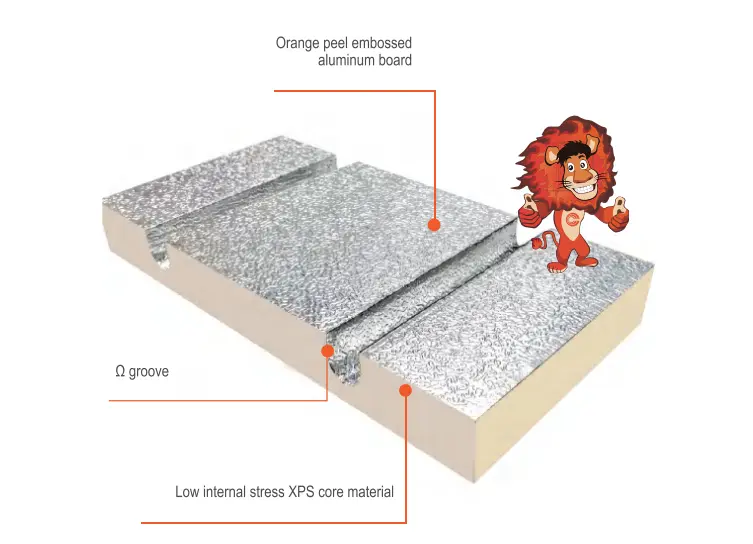

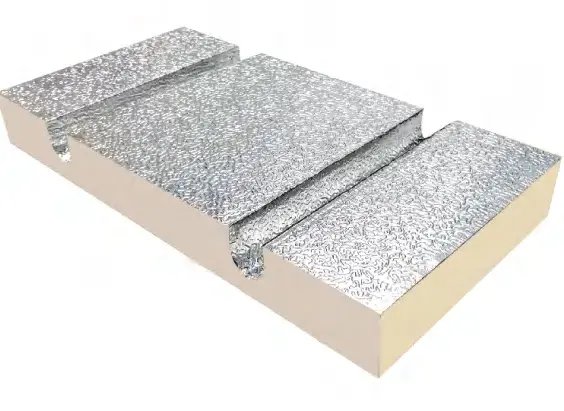

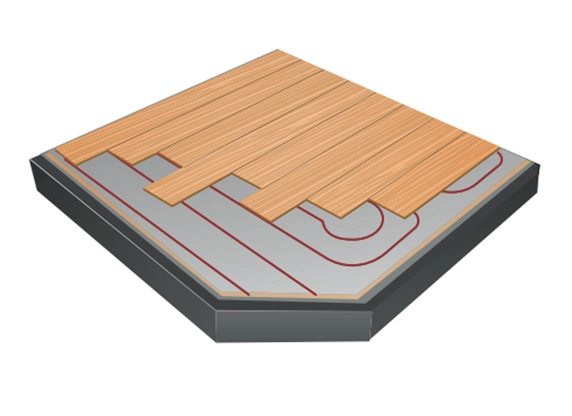

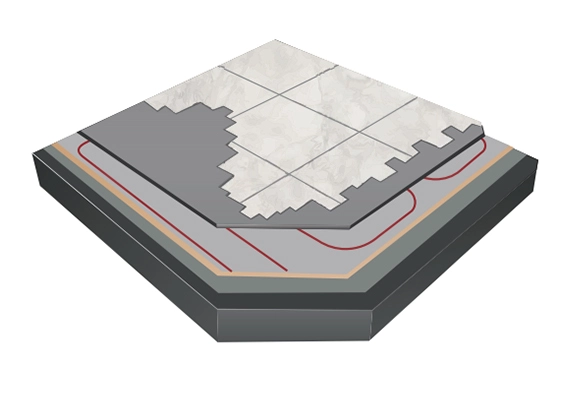

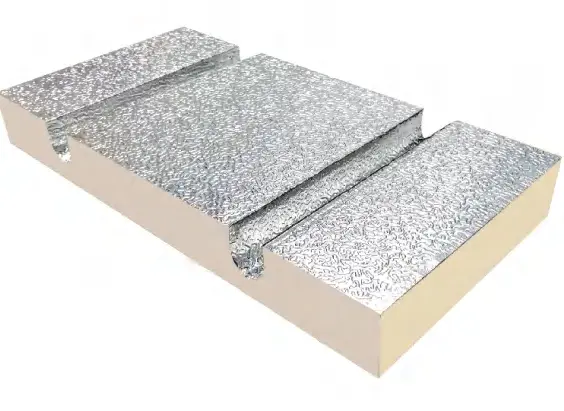

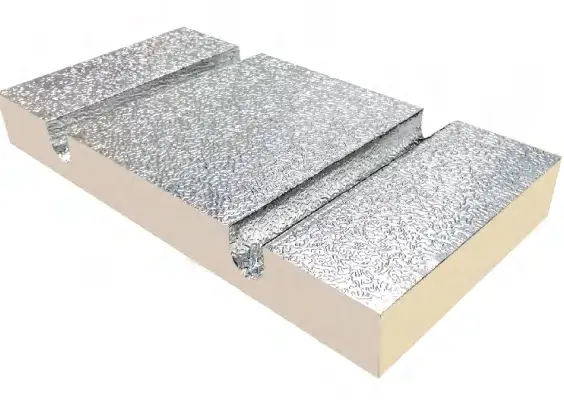

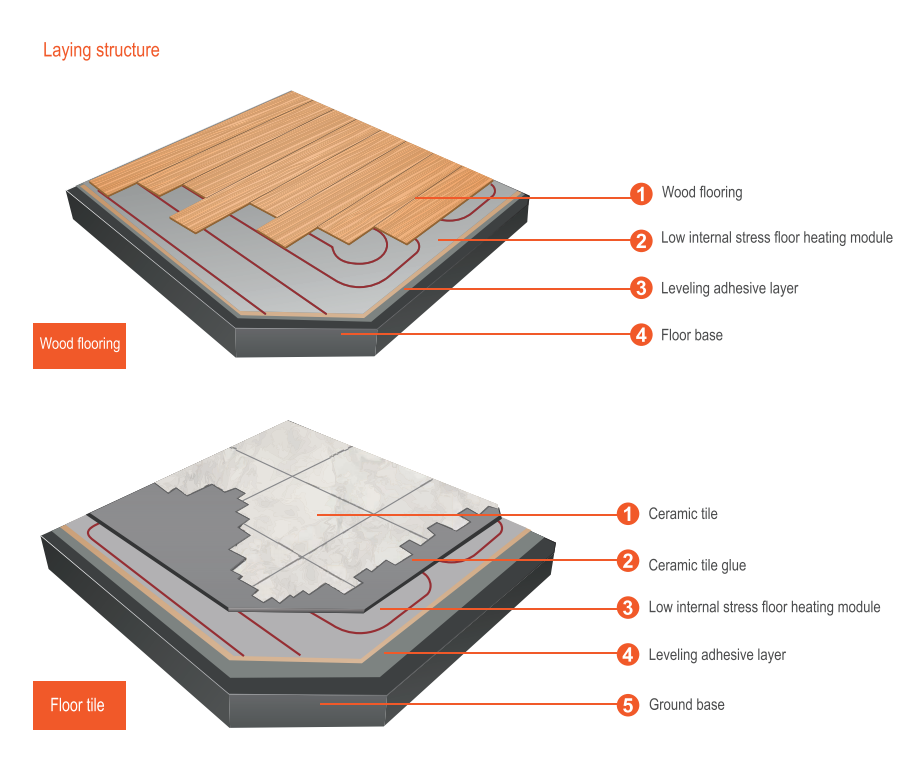

Our underfloor heating overlay boards use the company's self-developed high-strength, fluorine-free, bromine-free low internal stress extruded polystyrene (XPS) insulation boards as the main material, with a heat distribution layer attached to the surface. The UFH insulation board is pre-fabricated in the factory according to detailed drawings and assembled on-site. The surface of the underfloor insulation boards features evenly spaced Ω grooves for laying heating pipes.

SOHO's underfloor insulation board utilizes a patented low internal stress technology, making it a highly effective solution for floor heating systems. The under floor insulation boards are made from low internal stress extruded polystyrene (XPS), which ensures superior thermal insulation and stability. Available in various thicknesses (30mm, 35mm, 40mm, and 50mm), SOHO's under floor heating board modules are designed to accommodate both water-based and electric underfloor heating systems. They are suitable for installation under both wooden and ceramic tile flooring, offering versatility and efficiency in diverse heating applications.

Click the links below to check more details. Please feel free to contact us directly if you have any questions!

Leak-proof and quick maintenance: The water pipe is embedded in the Ω pipe groove for protection against leakage. During maintenance, you can simply lift the local floor.

Load reduction and energy-saving construction period: The no-backfilling process reduces the structural load by about 120kg/㎡, which can reduce costs and save construction time.

Saving floor height and cost: Reduce the backfilling pea stone cement and leveling layer by 50-70mm to reduce costs and save room net height.

Rapid heating and energy-saving: The heat is directly dissipated by the aluminum plate heat dissipation layer to increase indoor temperature, and the energy consumption is reduced by more than 50%.

Low-carbon environmental protection, sound absorption and noise reduction: Improved assembly rate, meeting the needs of green buildings. The patented core material has good sound absorption and noise reduction properties and good dimensional stability.

The under floor insulation boards are made of extruded polystyrene foam (XPS) which has a low internal stress level, which means that it resists deformation caused by temperature changes or foot traffic. This makes it ideal for use in underfloor heating systems, where it is important to maintain a stable surface to prevent damage to the heating system and to optimize heat transfer.

The under floor heating insulation boards have a high compressive strength, which ensures that they can withstand the weight of the flooring material, furniture, and foot traffic without being crushed or damaged. They are also moisture-resistant, which helps to prevent the growth of mold and mildew and ensure long-lasting performance.

Furthermore, the SOHO Low-internal-stress XPS Underfloor Heating Insulation Boards are easy to install and can be cut to size to fit any floor area. They also have excellent thermal insulation properties, which help to minimize heat loss and improve energy efficiency, resulting in lower heating costs.

Overall, SOHO Low-internal-stress XPS Underfloor Heating Insulation Boards are an excellent choice for ensuring a comfortable and efficient underfloor heating system.

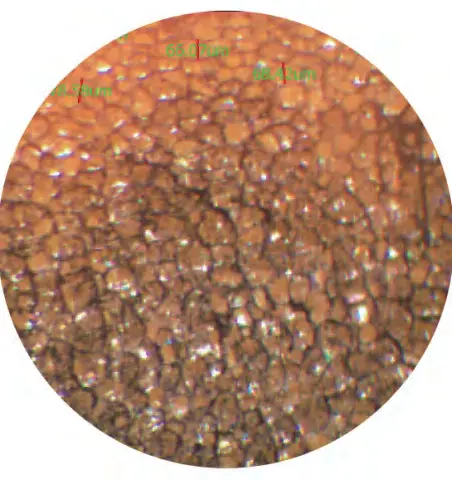

Learn More About Our Patented Technology - Low Internal Stress Technology.

Fluorine-Free & Bromine-Free XPS

The underfloor insulation boards are made from fluorine-free and bromine-free extruded polystyrene (XPS), ensuring a safer and more environmentally friendly product.

Low Heat Conductivity

The material has low heat conductivity, which helps maintain energy efficiency and prevents heat loss, improving the overall performance of the underfloor heating system.

Excellent Dimensional Stability

The UFH insulation board module maintains its shape over time, ensuring no bending or warping at the edges, even with prolonged use.

High Compressive Strength

With a compressive strength of over 1000 KPa, our under floor heating boards are highly durable, resistant to pressure, and able to withstand heavy loads.

Eco-Friendly & Non-Toxic

Certified by SGS as non-toxic and harmless, these modules are free from harmful substances such as heavy metals, benzene, and free formaldehyde, making them both safe for users and environmentally friendly.

Floor leveling:

The general contractor or decoration general contractor shall first ensure the flatness of the ground within the scope of the laying pipeline. The high-precision floor flatness shall reach 0-3mm, and the ordinary floor flatness shall be 0-5mm. There should be no unevenness, and all other work on the ground should be completed before construction.

Requirements for Basic Cleaning:

Before laying the floor heating module, it is necessary to clean up the debris and ash layer on the ground. The ground within the construction scope must be free of debris and floating soil.

Underfloor Heating Board Module Laying:

① Module Pre-laying;

② Adhere the module and ensure a good levelness.

③ Laying floor heating pipes

Pressure Test:

The water pressure test pressure should be 1.5 times the working pressure, but not less than 0.6 Mpa. Under the test pressure, the pressure should be stabilized for 1 hour, and the pressure drop should not exceed 0.05 Mpa, and there should be no leakage.

Laying surface layer.

The thickness of an XPS insulation board for underfloor heating system varies depending on several factors such as the type of insulation, the heating output, and specific building regulations in your area. Typically, the insulation board thickness for underfloor heating systems ranges from 30mm to 75mm.

In general, thicker underfloor heating floor boards can provide better thermal insulation and reduce heat loss to the sub-floor. However, thicker insulation also means greater overall floor height. So, the selection of the UFH insulation board thickness should consider the overall floor height, the heating output requirements, and the specific building regulations in your area.

It is always advisable to consult a professional underfloor heating system installer or a building engineer to determine the appropriate insulation thickness for your specific application. They can advise you on the recommended insulation thickness based on your specific requirements and local building codes.

When selecting an XPS underfloor heating board, consider the following factors:

♦ Board thickness

♦ Underfloor insulation R-value

♦ Type of underfloor heating system

♦ Room size

If you want to know more about our products, please leave a message or give us a call and we will get back to you as soon as possible.