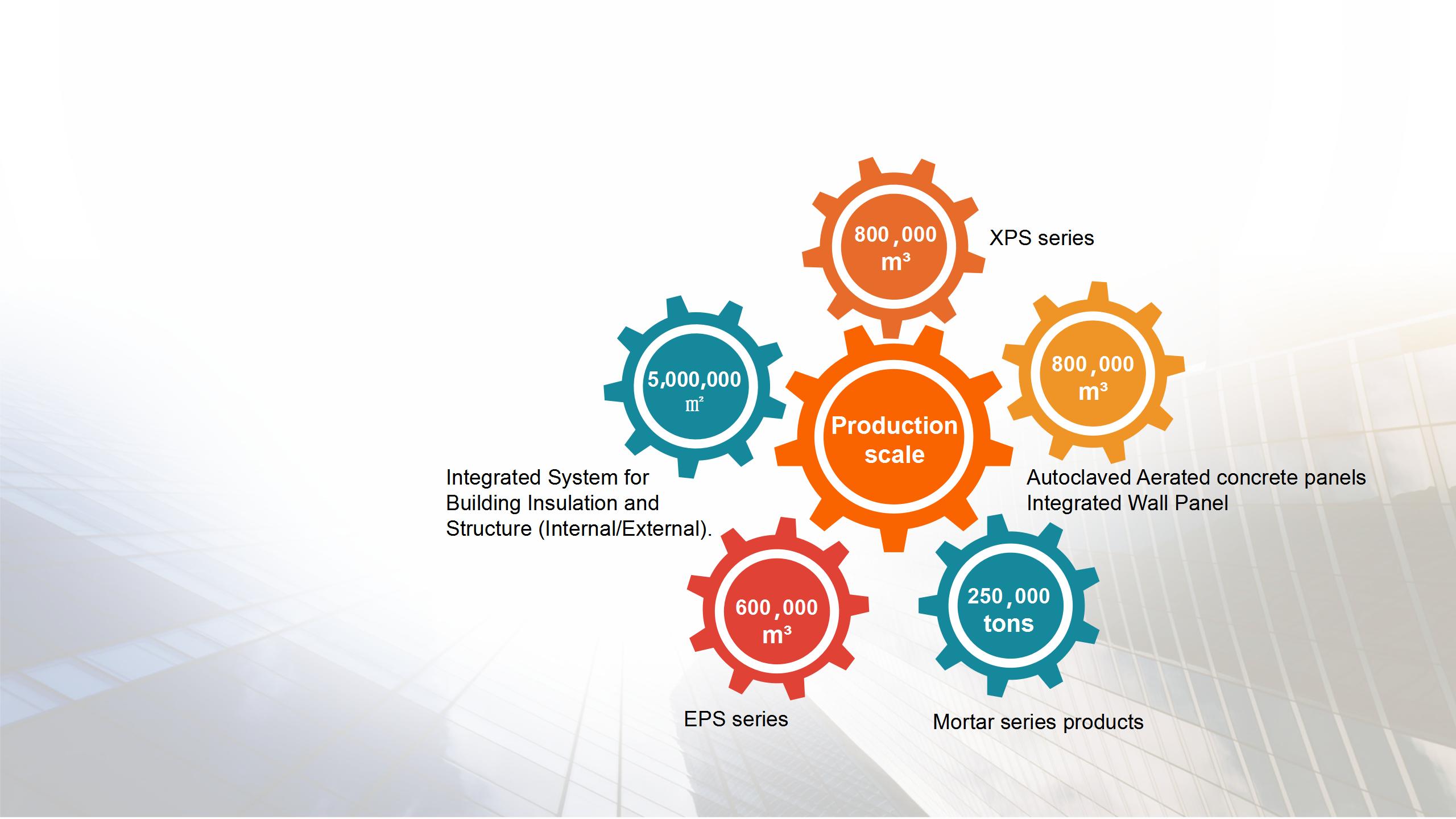

SOHO Group's annual production capacity includes 800,000 cubic meters of XPS series, 600,000 cubic meters of EPS series, and 250,000 tons of mortar products. They specialize in integrated building insulation and structural solutions, both internal and external, covering 5 million square meters. Additionally, they produce 800,000 cubic meters of steam-cured AAC concrete panels and integrated AAC insulation wall panels. Their production scale and sales performance rank among the top in the national construction insulation industry, positioning them as pioneers in green prefabricated and energy-efficient passive house wall solutions.

In the production of XPS extruded polystyrene boards, SOHO Group utilizes state-of-the-art German Klaus Maffei-Berstorff equipment. For EPS polystyrene foam boards, they employ advanced production lines imported from South Korea's Seong Hoon, featuring high-quality materials, precise sensors, and durable control systems. These imports ensure superior temperature and pressure control during XPS board production, surpassing domestic equipment in technological sophistication and craftsmanship. They achieve an annual output of 800,000 cubic meters for XPS series and 600,000 cubic meters for EPS series.

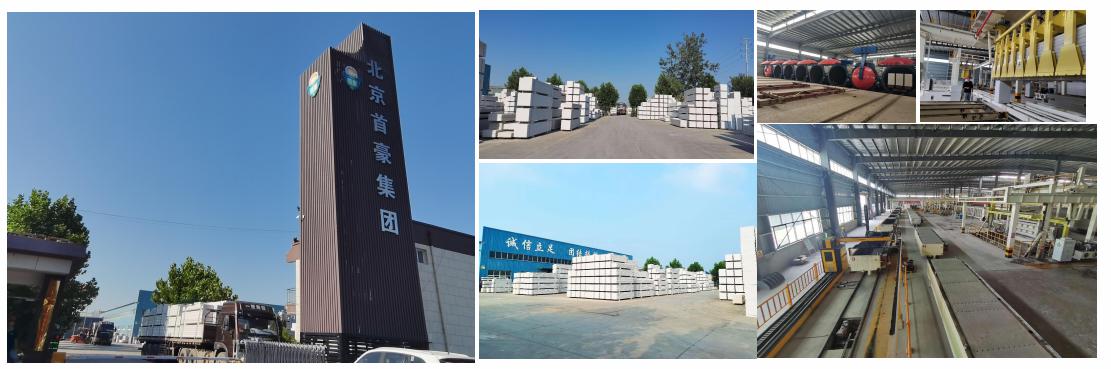

Established in 2020, the assembly industrial production base supports the industrial chain of Xiong'an New Area with a focus on promoting the "prefabricated green building materials" industry park. This facility began mass production of prefabricated building materials, with an investment scale of 100 million yuan and covering an area of 140,000 square meters. Equipped with advanced production facilities and strong capabilities, the factory ensures stable production of steam-cured AAC concrete products (ALC/AAC) exceeding 800,000 cubic meters annually, along with an annual production capacity of over 250,000 tons of special mortars and various ALC/AAC supporting materials and components. The products are favored by leading architectural design units for their balanced enhancement in lightweight, compressive strength, seismic resistance, sound insulation, fire resistance, thermal insulation, processing performance, waterproofing, and environmental protection standards.

Produces 800,000 cubic meters annually of steam-cured AAC concrete panels and integrated AAC insulation wall panels.