Autoclaved Aerated Concrete Panel or Block (AAC or ALC) is a lightweight porous silicate product made of siliceous materials (sand) and calcareous materials (lime, cement) as the main raw materials, mixed with gas-generating agent (aluminum powder), through the process of batching, mixing, pouring, pre-curing, cutting, autoclaving, curing and other processes.

As a professional manufacturer and supplier of AAC aerated autoclaved concrete panels and blocks, SOHO Group provides high-quality products. Our AAC panels and AAC concrete blocks have passed CE certification and the continuous implementation of ISO9001 quality management system, ISO14001 environmental management system and ISO45001 Occupational health and safety management system certification. Contact us now to receive the prices for our AAC panels and AAC concrete blocks.

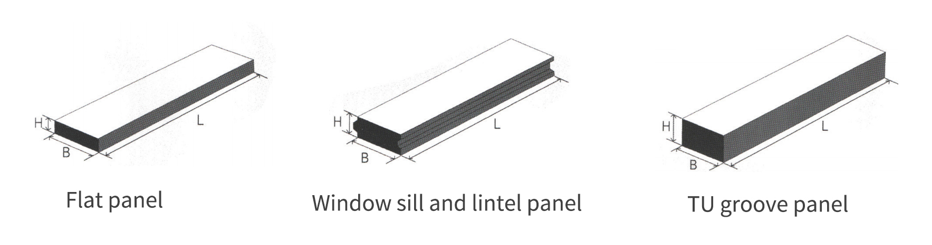

| Product Name | Specifications L*B*H(mm) | Construction Requirements |

| Exterior wall panel | ≤6000*600*200 | Notch, plane |

| ≤5750*600*150 | ||

| ≤3750*600*100 | ||

| Interior wall panel | ≤6000*600*200 | Notch, plane |

| ≤6000*600*150 | ||

| ≤4250*600*100 | ||

| Roof panel | ≤6000*600*250 | Notch |

| ≤5720*600*200 | ||

| ≤4500*600*150 | ||

| ≤3000*600*150 | ||

| Ultra-thin version | ≤2000*600*50 | Plane |

Performance Indicators of AAC Concrete Panel:

| Item | Unit | Technical performance indicators | ||||

| Density level | B04 | B05 | B06 | B07 | ||

| Dry density | Kg/m³ | 425 | 524 | 625 | 725 | |

| Compressive strength | Average value | MPa | ≥2.5 | ≥3.5 | ≥5.0 | ≥7.5 |

| Minimum value | ≥2.0 | ≥2.8 | ≥4.0 | ≥6.0 | ||

| Drying shrinkage value | mm/m | ≤0.50 | ||||

| Frost resistance | Mass loss | % | ≤5.0 | |||

| Post-freezing strength | MPa | ≥2.0 | ≥2.8 | ≥4.0 | ≥6.0 | |

| Thermal conductivity | W/(m·k) | ≤0.11 | ≤0.13 | ≤0.15 | ≤0.17 | |

| Radioactivity | Internal radiation index | / | 0.3 | |||

| External radiation index | 0.5 | |||||

| Fire resistance limit | h | 4 | ||||

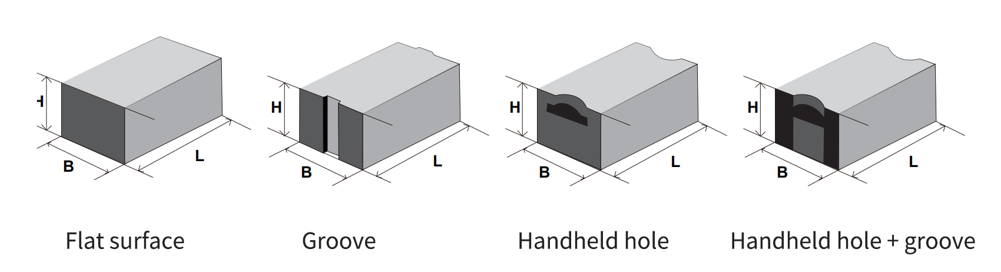

| Product Name | Specifications L*B*H(mm) | Grade | Structural requirements |

| Insulation Adhesive Block | 600*50*250 | BO4A2.5 | Plane |

| Insulation Block | 600*100*250 | BO4A2.5 | Plane, notch |

| 600*150*250 | BO5A3.5 | Handle port + notch | |

| 600*200*250 | BO6A5.0 | ||

| 600*250*250 | |||

| 600*300*250 |

*In addition to the above specifications, blocks can be customized.

Technical Indicators of AAC Concrete Block:

| Item | Unit | Technical performance indicators | ||||

| Density level | B04 | B05 | B06 | B07 | ||

| Strength level | *A2.5 A2.0 A2.0 | *A3.5 A2.5 A2.0 | *A5.0 A3.5 A2.0 | *A7.5 A5.0 A2.0 | ||

| Compressive strength | Average value | MPa | *≥2.5 ≥2.1 | *≥3.6 ≥2.7 | *≥5.0 ≥3.5 | *≥7.5 ≥5.0 |

| Minimum value | ≥2.0 | ≥2.8 | ≥4.0 | ≥6.0 | ||

| Dry density | Kg/m³ | ≤425 | ≤525 | ≤625 | ≤725 | |

| Thermal conductivity | W/(m·k) | ≤0.11 | ≤0.13 | ≤0.15 | ≤0.17 | |

| Drying shrinkage value | mm/m | ≤0.50 | ||||

| Frost resistance | Mass loss | % | ≤5.0 | |||

| Post-freezing strength | MPa | Greater than 80% of the average compressive strength of cubes | ||||

| ≥4.0 | ||||||

| ≥6.0 | ||||||

| Radioactivity | Internal radiation index | / | 0.3 | |||

| External radiation index | 0.5 | |||||

| Fire resistance limit | h | 4 | ||||

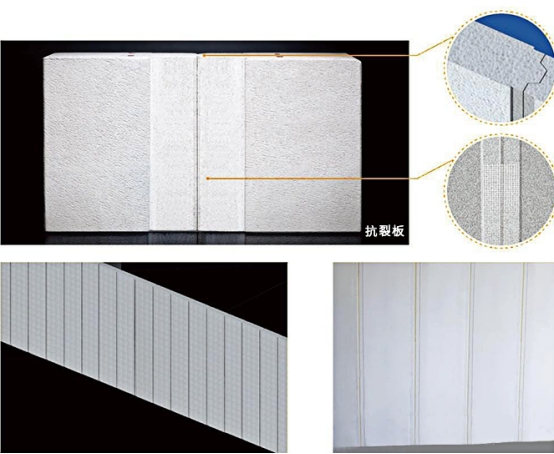

SOHO® AAC aerated autoclaved concrete panels and ACL products use special design forms between panels, beams, columns, floors, floor ceilings and bathroom return platforms. A groove with a depth of 3-5MM and a width of 50MM is processed at the joints of each autoclaved aerated concrete panel. When pasting the mesh cloth, the mesh is pressed into the groove. This ensures that the panel surface at the panel joint is flat with other panel surfaces after construction is completed, and also ensures the crack resistance of the panel itself and the finished wall.

The thermal conductivity of our AAC autoclaved aerated concrete panels and blocks B04-B07 is stable at 0.11-0.18W/(m·k). As the maintenance structure of the building's exterior wall, it can meet the dual-effect functions of building energy saving and thermal insulation without the need for any other insulation materials to be laid outside or inside.

SOHO's AAC concrete blocks and panels can greatly reduce the investment in building infrastructure and labor costs, reduce processes, shorten construction periods, require no maintenance, and speed up capital turnover. No internal and external insulation structures are required, saving costs.

The volume of 1 AAC product is equivalent to 18 red bricks, which can be dry-laid without masonry height restrictions.

Our AAC concrete panels and blocks are all made of inorganic materials and will not release harmful gases. The wall can effectively prevent the spread of flames, and the fire resistance limit is greater than 4 hours. It is a safer, more economical and more reliable building energy-saving and thermal insulation material.

The dry density of AAC products is 425Kg/m³-725Kg/m³, which can effectively reduce the weight of the building, reduce the investment in the foundation structure, and reduce the labor intensity during construction. The strength utilization coefficient of the aerated autoclaved concrete panels and blocks can reach 80% of its own strength, and the seismic performance is reliable.

AAC products are produced using natural environmentally friendly raw materials and non-sintering processes. The products not only comply with the government's policy of protecting ecology and agricultural land, but also have excellent thermal insulation functions and greatly reduce the energy consumption of buildings.

The uniform closed pore structure of AAC products has excellent sound absorption and sound insulation performance.

The closed pore structure of AAC products greatly reduces its water absorption rate, and combined with other anti-seepage measures, it can effectively prevent the diffusion and penetration of water molecules.

Looking for eco-friendly and durable building materials? Look no further than autoclaved aerated concrete (AAC) products. Our range includes aerated autoclaved concrete panels, Autoclaved aerated concrete AAC block, and autoclaved aerated concrete blocks. These products offer superior strength and insulation properties, and are an ideal choice for sustainable building practices. Whether you're looking for AAC blocks or AAC wall panels, our products come from leading brands and suppliers in the industry. Choose AAC autoclaved aerated concrete blocks for sale from our reliable manufacturers and suppliers. We offer a range of options to fit your budget and project needs. From AAC panel price to aerated concrete wall panels, we have what you need at competitive prices. Our autoclaved aerated concrete panel and block options are ideal for everything from building blocks to building panels. Consider AAC concrete blocks for your next project and experience the difference in quality and sustainability.

If you want to know more about our products, please leave a message or give us a call and we will get back to you as soon as possible.